Depuis 2000, nous nous lançons des défis hors normes que nous transformons en réalité. Innovation après innovation, nous contribuons à accélérer le développement du secteur des véhicules électriques, au cœur des enjeux actuels de mobilité durable.

en savoir plus

Défis technologiques et humains, les Venturi Global Challenges nous permettent de repousser les limites du véhicule électrique tout en rendant hommage aux plus grandes épopées automobiles du siècle dernier.

en savoir plus

L’emblématique marque française de moto Voxan a pris le virage de la motorisation électrique en 2010 lors de son rachat par Venturi. La Wattman, symbole de cette nouvelle direction, explore aujourd’hui la possibilité de franchir des vitesses encore jamais vues.

en savoir plus

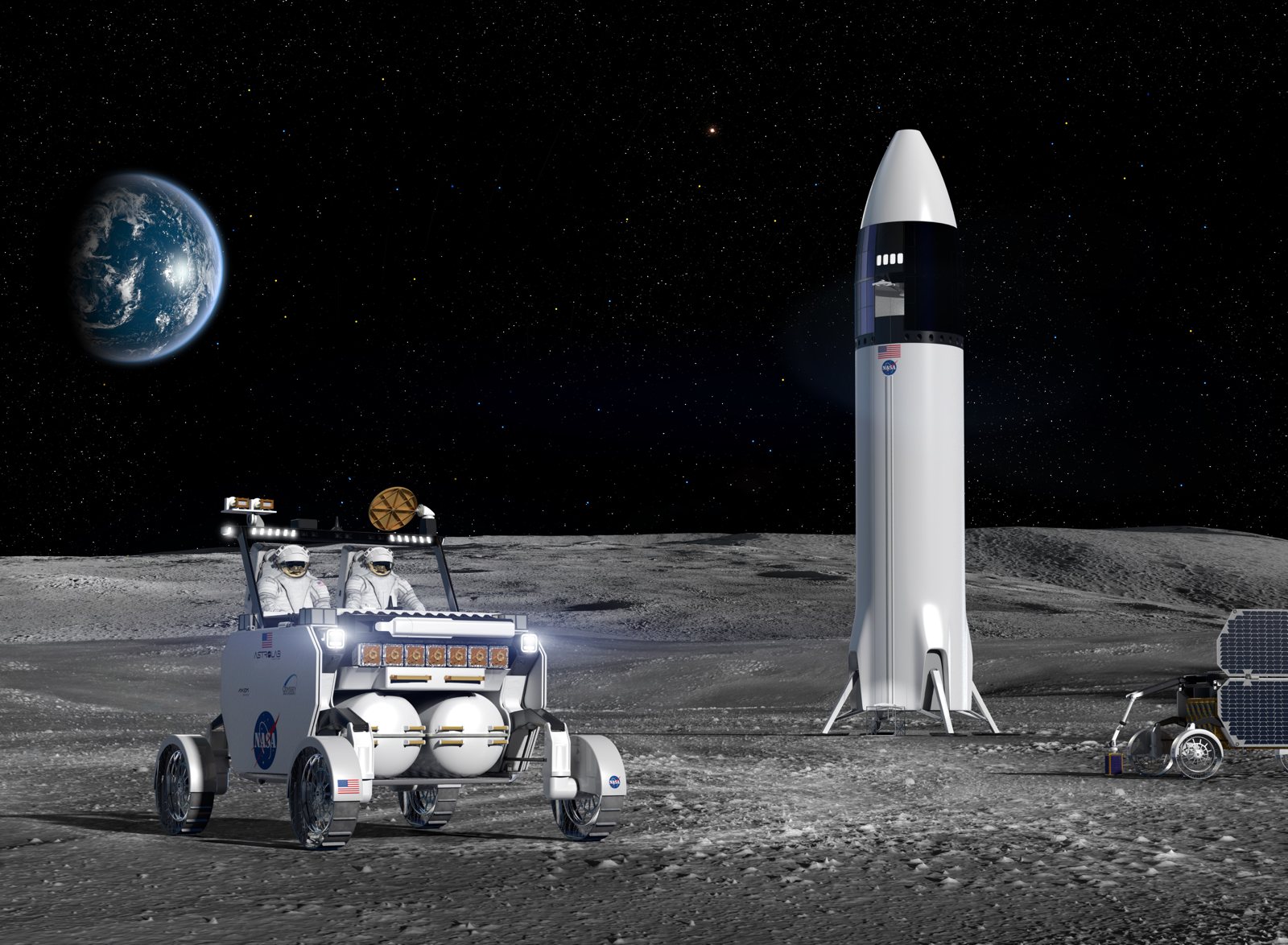

Venturi Lab conçoit et fabrique des solutions de mobilité capables d’affronter les conditions environnementales extrêmes de la Lune et de Mars. La société a été co-fondée en Suisse en 2021 par Gildo Pastor, Président de Venturi.

en savoir plus

En 2014, Venturi a été la première équipe à s’engager en Formula E. Au cours de ses 8 saisons en monoplace électrique, la marque a laissé une trace indélébile dans l’histoire de la discipline.

en savoir plus

La NASA octroie un contrat portant sur le développement d’un véhicule lunaire à un partenaire stratégique de Venturi

Plus d’information